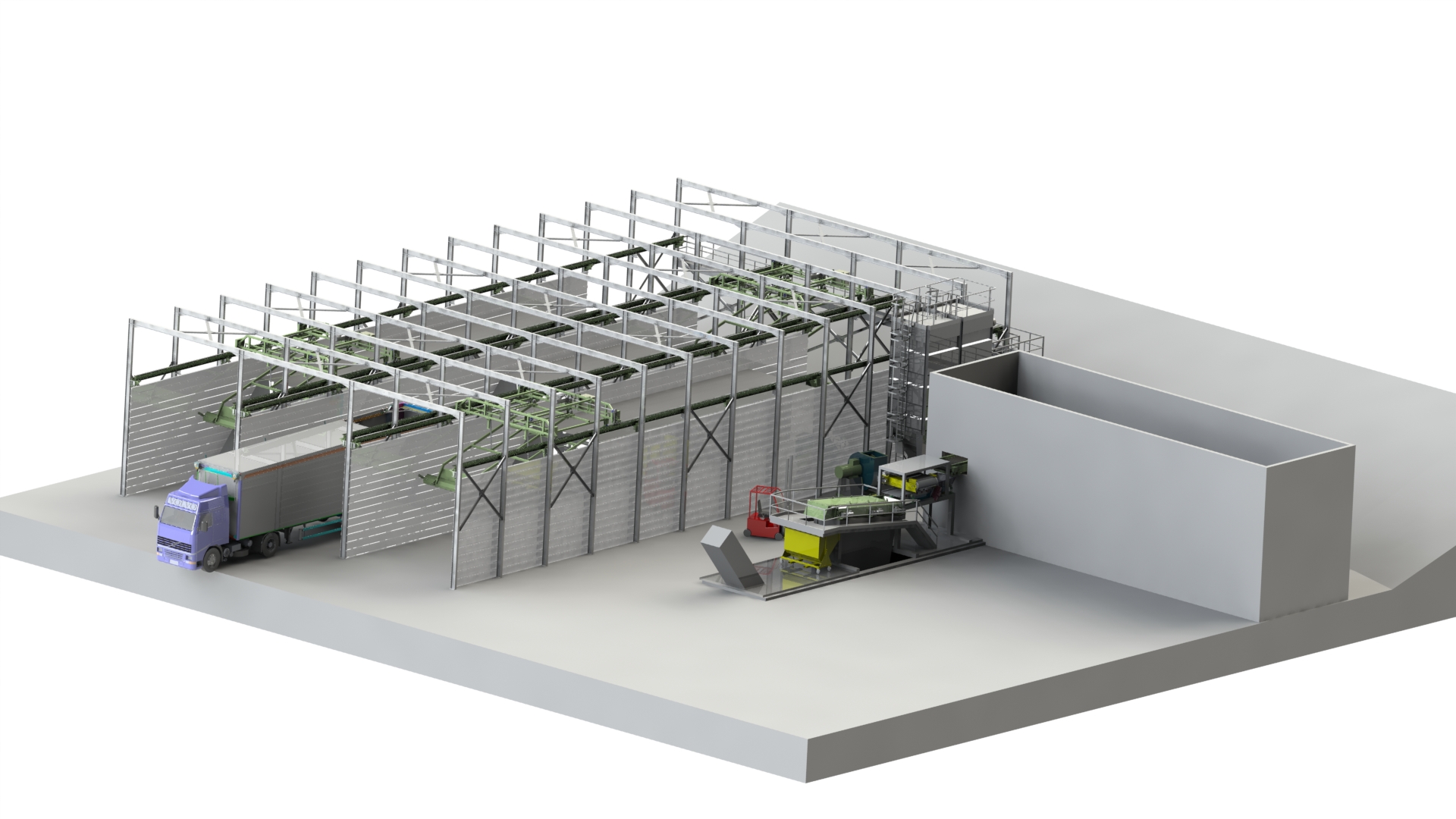

Logistic facilities for alternative fuel

The logistic workshop for alternative fuel is responsible for the receipt, storage and the fuel supply of the process.

RMIS provides a turnkey process, from receipt to injection, adapted to any type of solid fuel: SRF / RDF, biomass, wood

Method :

- Unloading the truck

The truck is unloaded directly onto the ground, inside the unit. We do not use a pit, nor any unloading or handling equipment. The driver unloads with complete autonomy in order to leave the factory quickly, without causing any logistical downtime. - Material storage

From the windrow unloaded in bulk by the truck, storage of the material is automatically carried out by the R-Stock, up to a height of 4 metres. - Extraction of the material

In the event of a material or fuel request, the R-Stock performs an additional linear movement and feeds the conveyor line until it is fed into the burner.

The unit is automatically purged completely so that no waste material remains. - Safeguarding the waste flow and the feed process

The use of a star screen allows waste outside of particle size specification to be removed, while the Overband takes care of the removal of ferrous elements. - Metering

A belt feeder delivers the fuel to be fed into the furnace.

The RMIS added value :

All the equipment in these workstations is produced in-house, using simple and robust materials with excellent cost control and respect for deadlines. They offer huge storage capacities for a reduced investment.